KVC UK Ltd

A valve manufacturer providing industrial pipeline valves such as Gate valves, Globe valves, Check valves & Ball valves. Various standards such as API, ASME applicable.

A valve manufacturer providing industrial pipeline valves such as Gate valves, Globe valves, Check valves & Ball valves. Various standards such as API, ASME applicable.

Deeply anchored in a culture of quality and reliability KVC UK Ltd stands as the forefront of engineering excellence. We specialize in the design and manufacture of Ball Valves for the Oil, Gas, Chemical, Petrochemical, Pipeline and Water industries. Headquartered in Glasgow, Scotland, our Center for Research & Development is endowed with strong design & engineering capabilities. This dedicated facility enables us to achieve continuous technological upgradation in the existing product portfolio as well as introduce industry-leading new products at optimized prices.

All our valves are manufactured to the highest quality standards and are fully tested to comply with various industry norms such as API Q1/API 6D, SIL IEC 61508, PED & ISO 9001: 2015. We have the ability to offer short lead-times, even on non standard valves. With a comprehensive range of stock valves available, we can easily accomodate last-minute client demands.

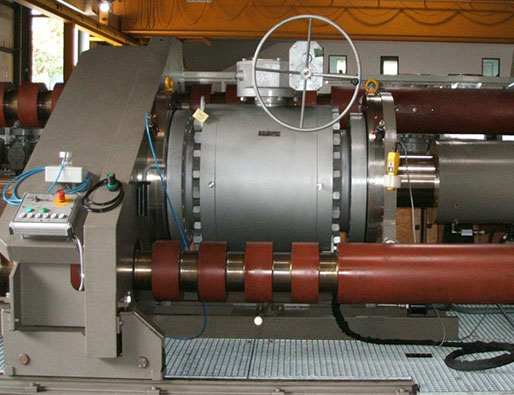

KVC UK Ltd Trunnion Mounted bolted construction Ball Valves are designed and manufactured in accordance with the latest industry standard. Valve Range 2” – 48” Class 150 -2500, API 5000, API 10000

Special face to face dimensions can be supplied. All valves are available in Full or Reduced Bore, with Raised Face, Ring Type Joint, Hub End, Butt Weld or Socket end connections. Pressure rating range from ANSI 150 thru ANSI 2500, compact flanges and higher pressure ratings are available on request.

Valves are supplied as Lever Operated, Gear Operated or Actuated to customer’s specification. Valves are manufactured from forged rings, which ensure a high integrity material grain structure and improved sealing between the components.

Standard Sealing is by O-rings and Graphite rings. The Graphite ring continues to provide a seal in the event of a fire. O-rings can be supplied suitable for AED (Rapid Gas Decompression) applications in a variety of materials. Energised Lip seal designs are also available to cope with more extreme service conditions and temperatures.

The core design has many standard key features including:

Valves can be supplied Full or Reduced Bore and are manufactured in either cast or forged construction. Bolted and Screwed Body connections give ease of service and maintenance on site. Valves can be supplied with either Raised Face, Ring Type Joint, Socket Weld or Screwed End connections. Pressure rating is from ANSI 150 thru ANSI 2500. Higher pressures can be supplied on request. Valves are supplied with Lever or Gear Operator.

Cast and forged construction in stainless steel, carbon steel materials, with various trims to suit any applications. Pressure Classes form ANSI 150 – 2500, in sizes ranging from ½” to 24” (Subject to Design / Material)

Cast and forged construction in stainless steel, carbon steel materials, with various trims to suit any applications. Pressure Classes form ANSI 150 – 2500, in sizes ranging from ½” to 12” (Subject to Design / Material)

Cast and forged construction in stainless steel, carbon steel materials, with various trims to suit any applications. Pressure Classes form ANSI 150 – 2500, in sizes ranging from ½” to 24” (Subject to Design / Material) Available Design variations include, Piston, Ball, Swing & Wafer Types.

KVC UK Ltd offer our customers a range of services and aftermarket care ranging from Parts and spares – We hold stock or can offer quick manufacture and turn around for spare parts or replacement seals, for our own products and supply as well as others.

Bespoke design service – In order to meet the most demanding or specific conditions that cannot be satisfied by a standard valve.

Extensive testing facilities – Suitable up to 48” Valves, throughout of range of worldwide KVC UK Ltd approved facilities.Repair, Refurbishment, overhaul and retest of any manufacture of Trunnion mounted ball valve.